AST

About Advanced Substrate Technologies Pte. Ltd.

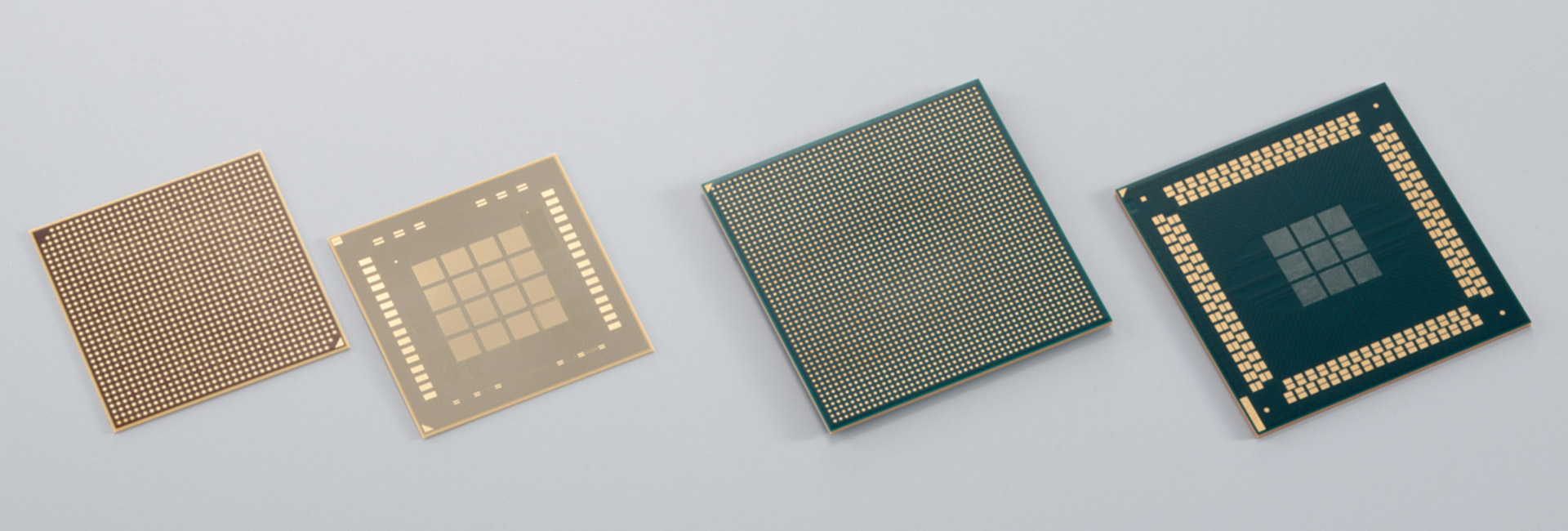

We are a Singapore-based subsidiary of TOPPAN Holdings Inc., a Japanese pioneer in printing technologies and a leading supplier of high-quality Flip Chip Ball Grid Array (FC-BGA) substrates. We are the first factory in Singapore to pioneer the manufacturing of high-end FC-BGA substrates used in cutting-edge semiconductor products such as network switches and artificial intelligence (AI)/machine learning (ML) devices.

Additionally, our facility will conduct research and development (R&D) aimed at advancing substrate technologies to meet the evolving performance requirements of future products in these domains. Broadcom Inc., a global technology leader specializing in semiconductor design, enterprise software, and security solutions, is also actively supporting the establishment of this state-of-the-art manufacturing facility in Singapore.

Our Research & Development

Do you thrive on developing groundbreaking technologies that lead to amazing new products? Are you meticulous and committed to excellence, always aiming for extraordinary results? Come see what you can achieve with AST R&D team! We believe that new ideas swiftly become remarkable products. With your passion and dedication, there’s no telling the impact you’ll make.

Company Overview

Our AST R&D team is on a mission to transform AI and develop groundbreaking hardware. We’re creating innovative solutions for tighter, quicker, and more dependable integration of processing and memory, moving beyond the limitations of current substrate technologies. We leverage cutting-edge semiconductor processing technologies, including Chemical Mechanical Planarization, to produce high-performance substrates with 10x increase in interconnect density, paving the way for packages with up to a trillion transistors.

Position Summary

We are looking for an experienced and highly skilled Simulation Engineer to join our Process R&D team. This critical role involves developing, implementing, and utilizing sophisticated computational models to simulate and optimize the Chemical Mechanical Planarization (CMP) process specifically for dual damascene structures incorporating organic dielectrics and copper metallization. The ideal candidate will bridge the gap between theoretical modelling and practical manufacturing challenges to enhance process yield, uniformity, and efficiency.

Key Resposibilities

- Develop and validate predictive simulation models to accurately represent the complex physical and chemical phenomena occurring during the CMP process, focusing specifically on interactions between copper, organic dielectric materials, slurry chemistry, and pad mechanics.

- Utilize advanced simulation software to analyse material removal rates (MRR), topography evolution, defect formation mechanisms, and process non-uniformity.

- Collaborate closely with process engineers and material scientists to integrate simulation data with experimental results, enabling faster process cycles of learning and troubleshooting.

- Optimize process parameters (e.g., pressure, platen speed, slurry composition, pad conditioning) through simulation to achieve global and local planarization targets for dual damascene structures.

- Analyse and interpret simulation outputs to identify potential issues such as erosion, dishing, and delamination specific to the material interfaces, providing actionable recommendations to improve process performance and yield.

- Design simulation experiments (DoE) and communicate technical findings clearly to multidisciplinary teams and management via detailed reports and presentations.

- Stay abreast of the latest advancements in CMP technology, organic dielectric materials, and computational modelling techniques to maintain a competitive edge in semiconductor manufacturing.

Location & Commitments

- Premises located in 9 Pesawat Drive, Singapore 619607

- Permanent, full-time role working 40 hours per week

Required Qualifications

- Education: Master’s or Ph.D. in Chemical Engineering, Materials Science, Mechanical Engineering, Physics, or a related field with a strong focus on computational modelling or semiconductor processing.

- Experience: Minimum of 3-5 years of experience in process modelling or simulation within the semiconductor industry, specifically involving CMP or a related surface finishing technology.

- Technical Skills: Deep understanding of fluid dynamics, reaction kinetics, contact mechanics, and material science principles related to CMP.

- Software Proficiency: Hands-on experience with commercial simulation packages (COMSOL Multiphysics, ANSYS Fluent/Mechanical) and proficiency in programming/scripting languages (Python, MATLAB) for data analysis and model customization.

- Domain Knowledge: Familiarity with semiconductor fabrication processes, particularly dual damascene architecture, copper interconnects, and properties of organic dielectric materials.

Preferred

- Direct experience with specific CMP modelling software or internal proprietary tools.

- Knowledge of statistical analysis software and methodologies (e.g., JMP, Minitab).

- Experience in high-performance computing (HPC) environments for large-scale simulations.

Contact us to apply

If you believe you possess the qualifications for this position, please submit your resume and cover letter to our HR team at hr_career@ast-sg.com.

Why Join Us?

- Be at the forefront of semiconductor innovation.

- Collaborative, fast-paced environment with a focus on cutting-edge R&D.

- Opportunity to make a tangible impact on next-generation microelectronics performance.

- Competitive salary, comprehensive benefits, and opportunities for professional growth.

Closing Statement

AST is dedicated to creating a workplace that is diverse, equitable, and inclusive, where every employee feels appreciated, respected, and empowered to share their unique perspectives.

Connect With Us!

Find out our latest happenings in social media:

To apply for this job email your details to hr_career@ast-sg.com