AST

About Advanced Substrate Technologies Pte. Ltd.

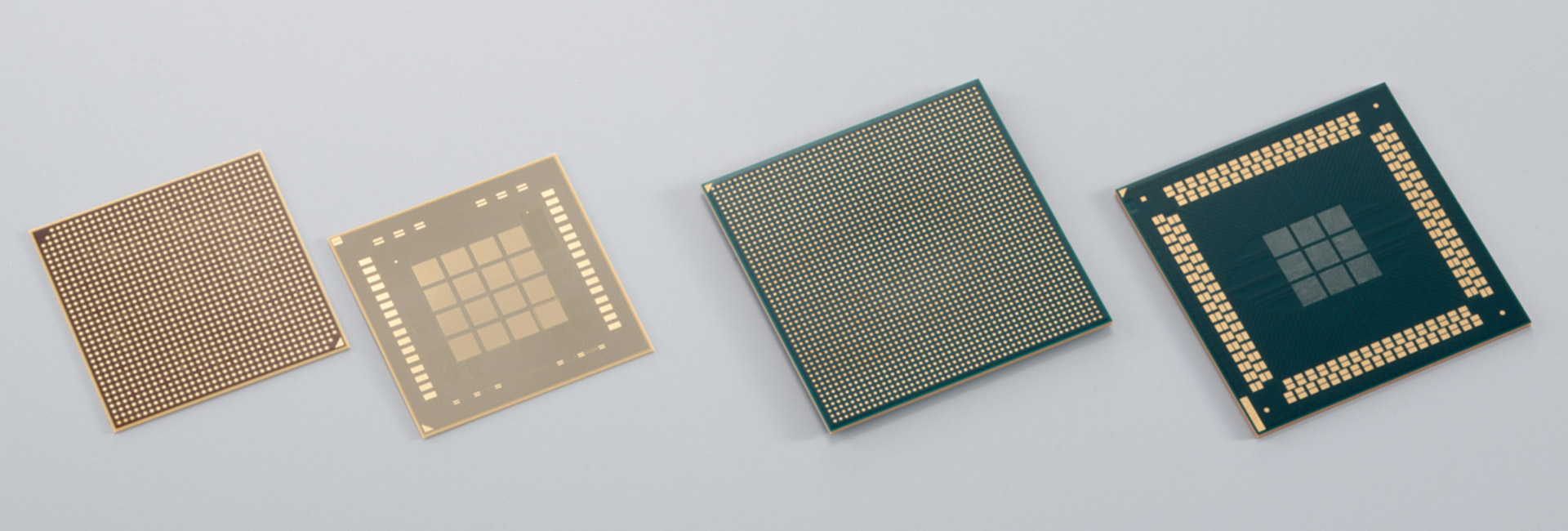

We are a Singapore-based subsidiary of TOPPAN Holdings Inc., a Japanese pioneer in printing technologies and a leading supplier of high-quality Flip Chip Ball Grid Array (FC-BGA) substrates. We are the first factory in Singapore to pioneer the manufacturing of high-end FC-BGA substrates used in cutting-edge semiconductor products such as network switches and artificial intelligence (AI)/machine learning (ML) devices.

Additionally, our facility will conduct research and development (R&D) aimed at advancing substrate technologies to meet the evolving performance requirements of future products in these domains. Broadcom Inc., a global technology leader specializing in semiconductor design, enterprise software, and security solutions, is also actively supporting the establishment of this state-of-the-art manufacturing facility in Singapore.

Responsibilities

Planning and Achievement of Production and Profit Plans

- Develop and manage production schedules based on customer forecasts and confirmed orders

- Ability to optimize resource allocation for each production process and make necessary adjustments to ensure on-time delivery.

- Development and execution of profit plans, both mid-to-long term and monthly, to ensure financial targets are met.

- Formulation and implementation of production plans at all levels—master scheduling, medium-term scheduling, and detailed short-term scheduling.

- Promote automation and digital transformation (DX) in production processes through the effective use of integrated systems

Quality (Q) Management

- Collaborate with the quality assurance team and other departments to plan, monitor, and improve quality across all processes, from design and manufacturing to shipment.

- Prevent defects and operational issues proactively to enhance customer satisfaction, product reliability, and overall brand value

- Implement timely and effective corrective actions in the event of quality-related incidents

Delivery (D) Management

- Oversee and adjust production schedules. Use BI tools and data analytics to optimize manufacturing efficiency

- Configure production parameters within production management systems as required

- Formulation and adjustment of production schedules, input planning, and outbound logistics management

- Create and adjust an appropriate production schedule based on demand forecasts and order information

- Production progress monitoring

- Monitor progress across all production stages in real time, identifying and resolving delays promptly

- Risk management

- Conduct proactive risk assessments related to delivery schedules, disseminating information to relevant stakeholders, and implement preventive or corrective measures

- Resource Management

- Propose efficient utilization of personnel, equipment, and materials to maximize profitability

- Adjustment & Coordination

- Maintain close coordination with internal departments (Sales, Procurement, Quality Control) and external suppliers to ensure seamless operations

- Customer support

- Manage delivery related communication with clients, fostering trust and long-term business relationships

- Improvement activities

- Pursue ongoing improvements in delivery management processes to enhance accuracy, operational efficiency, on-time performance, and customer satisfaction in order to maximize profits

- Export and Logistics Management (Product Shipments)

- Manage transportation partner selection, packaging, and delivery scheduling

- Drive cost reduction and operational efficiency while ensuring compliance with delivery timelines and service quality standards

- Sub-Contractor Management

- Oversee the selection of subcontractors, negotiate contracts, manage project progress, ensure quality assurance, control costs, mitigate risks, and maintain effective communication channels

Location & Commitments

- Premises located in 9 Pesawat Drive, Singapore 619607 or any other location

- Permanent, full-time role working 40 hours per week

Job Requirements

Professional qualifications:

- Bachelor’s degree or higher

- 3 to 5 years of experience in production management within the manufacturing industry

- Experience in a similar role within the production management department of a semiconductor-related manufacturing company is a plus

Expertise and Skills

- Knowledge of Production Management

- Fundamental knowledge and practical experience in all aspects of production management, including production planning, inventory control, quality management, process management & etc.

- Fundamental knowledge of semiconductor-related manufacturing processes, including photolithography, etching, thin-film deposition & etc.

- Production Planning and Scheduling Skills

- Ability to develop and analyse efficient production plans based on demand forecasts.

- Data Analysis Skills

- Experience in using production schedulers and BI tools for data analysis.

- Ability to optimize processes and identify root causes of defects through the collection and analysis of production data.

- Project Management Skills

- Ability to effectively plan, execute, and monitor projects to support the achievement of objectives.

- Supply Chain Management Skills

- Establishing an efficient supply chain through the procurement of raw materials, inventory control and logistics optimization, accompanied by knowledge and experience in regulatory compliance.

- Cost Management and Optimization Skills

- Enhancing cost efficiency through the analysis of production costs as well as the planning & implementation of cost reduction measures

- Continuous Improvement (Kaizen) and Problem-Solving Skills

- Ability to drive improvement initiatives within one’s department and to resolve emerging issues promptly and effectively.

- Candidates with experience in automation and digital transformation (DX) in production management within the manufacturing industry, as well as those possessing strong management skills, are welcomed to apply.

- Quality Control and Quality Assurance Skills

- Knowledge of quality control methodologies such as Statistical Process Control (SPC)

Competency:

- Problem solving skills

- Ability to quickly and effectively identify a wide range of issues that arise during production and implement appropriate solutions.

- Communication skills

- Ability to exchange information smoothly with both internal and external stakeholders and to build effective cooperative relationships.

- Coordination with other departments and external partners is also essential.

- Planning & Scheduling skills

- Ability to develop production plans and schedules, analyse variances between forecasts and actual results, and propose improvement measures. (Inclusive of demand forecasting and inventory management.)

- ·Data Analysis skills

- Ability to collect and analyse production data to drive operational improvements and support decision making.

- This includes the use of statistical methods and core systems such as ERP and MES.

- Flexibility and Adaptability

- Ability to respond swiftly to market fluctuations and technological advancements by appropriately adjusting production processes.

- Demonstrates a proactive approach to adopting new methodologies and tools.

Attributes:

- A desirable candidate is one who possesses a comprehensive understanding of market trends in the semiconductor and packaging industries, can take a broad, strategic view of the business environment, identify gaps and developments in relation to their own department, and take appropriate action accordingly.

- Strong interpersonal and communication skills are essential for effective collaboration across multiple departments.

- A cooperative and collaborative personality is highly desirable.

Others:

- The role will also include responsibilities in the customer service department, such as managing customer forecasts, order entry, production status communication, shipping arrangements, and invoicing.

- Experience in customer liaison or order/invoice management within the manufacturing industry is considered an advantage.

- While the position generally involves weekday daytime shifts, weekend or holiday work may be required based on the instructions of the immediate supervisor.

- The role may involve working in a cleanroom environment.

- Business-level proficiency in Japanese is highly desirable for effective communication.

Contact us to apply

If you believe you possess the qualifications for this position, please submit your resume and cover letter to our HR team at hr_career@ast-sg.com.

Why Join Us?

-

You will have the Opportunity to Make an Impact as pioneer employees in shaping our company’s culture, processes, and success from the ground up.

-

You will have ample opportunities for Career Growth and Advancement as our company continues to grow.

-

We do embrace Technology AI Innovation and Agile Work Environment where ideas are valued and implemented quickly.

-

You will have more chances to take on Ownership initiatives with higher Recognition from the Management.

-

We do offer Competitive Compensation, Benefits and Perks as we benchmark ourselves against the market data.

-

We fully understand the importance of Work-Life Balance so we do offer Flexible Work Arrangement and Flexi–Time in the company.

-

We are planning to introduce a Shuttle Bus Service that will transport employees from designated MRT stations, with potential expansion to include a pickup point at Johor customs.

-

Our facility will have a Multi-Purpose Room cater for religious prayer, meditation time and nursing purposes.

Closing Statement

AST is dedicated to creating a workplace that is diverse, equitable, and inclusive, where every employee feels appreciated, respected, and empowered to share their unique perspectives.

Connect With Us!

Find out our latest happenings in social media:

To apply for this job email your details to hr_career@ast-sg.com