Denounce with righteous indignation and dislike men who are beguiled and demoralized by the charms pleasure moment so blinded desire that they cannot foresee the pain and trouble.

Read More

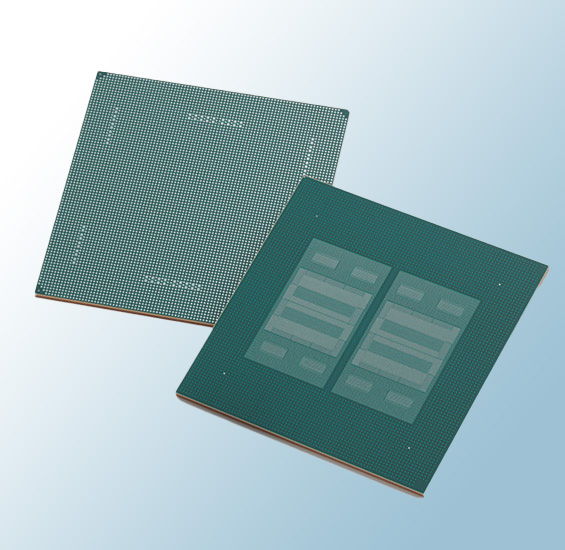

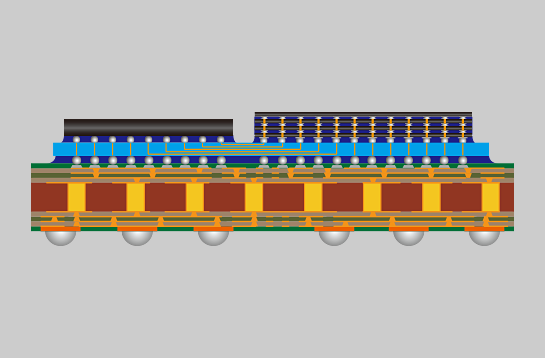

FC-BGA (flip chip ball grid array) on a high density semiconductor package substrate allows high speed LSI chips with more functions.

We have developed ultra high density wiring substrates with our original microfabrication and build-up wiring technologies, offering products supporting current semiconductor microfabrication.

With a growing demand for LSIs for automotive SoC or high-end processors (server, AI, network) as well as for PCs or game devices, we provide comprehensive support from substrate design to production. Solutions for lead-free and halogen-free products are also available.

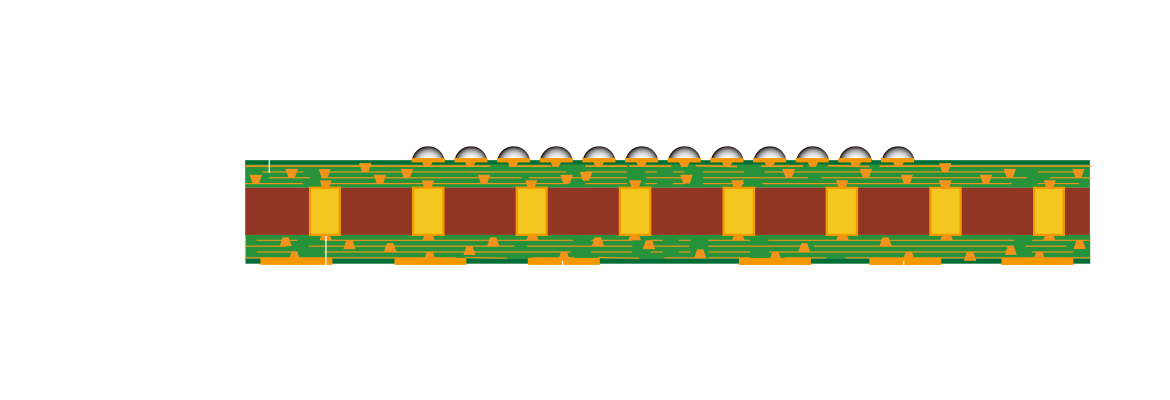

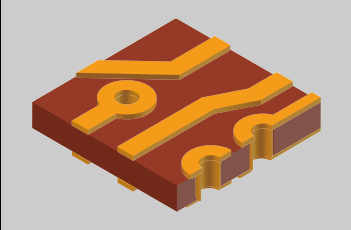

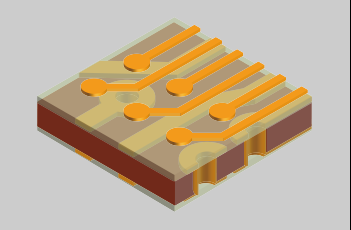

Core Process

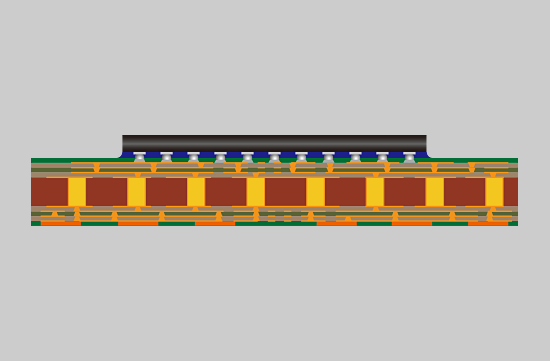

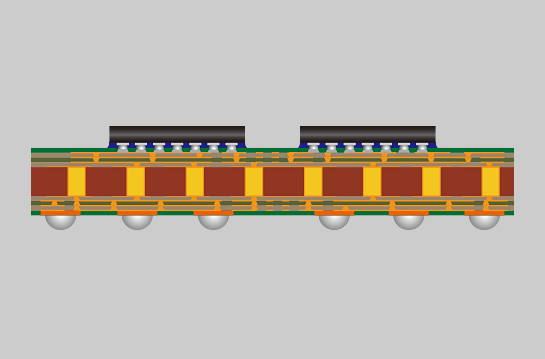

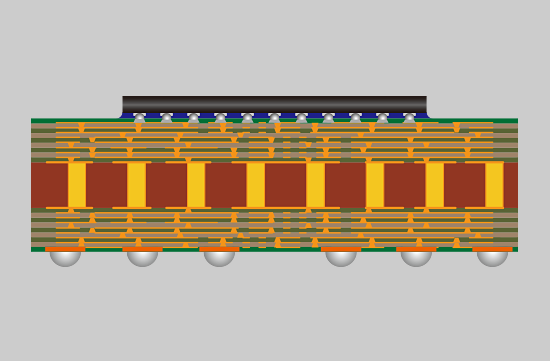

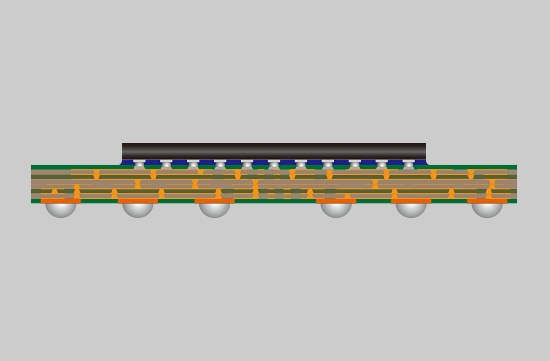

Drill holes in the core material and plate it with copper. Then remove the copper except for a circuit pattern area.

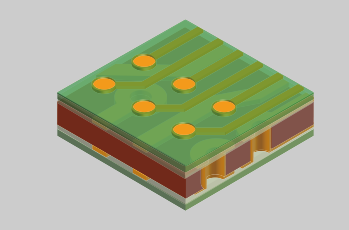

Build-up processing

Expose a circuit pattern to directly form circuit with copper plating. Repeat this treatment and laminate (build up)

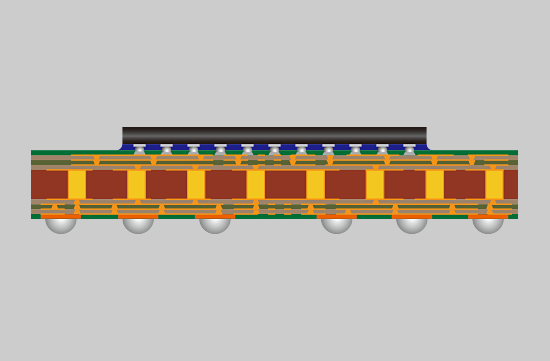

Outer layer Process

After applying solder resist, place solder bumps where LSI chips (die) will be mounted. After cutting into each pieces, inspect appearance and electric characteristics.

Network device

(ASIC)

Server / PC

(CPU)

AI Processor

(AI)

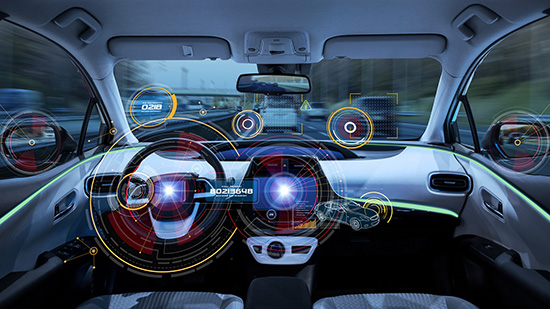

Automotive

(Infotainment / ADAS)

Home Game Console

(SoC)

Graphic Processing Unit

(GPU)

FC-BGA

FC-LGA

Multi-chip FC-BGA

Ultra-multilayer FC-BGA

Coreless FC-BGA

2.3/2.5D FC-BGA

※ For the respective product line, please contact us directly for prototyping or evaluation purposes